Da sợi nhỏ gây ngạc nhiên với sức mạnh thân thiện với môi trường

Aug 28, 2025

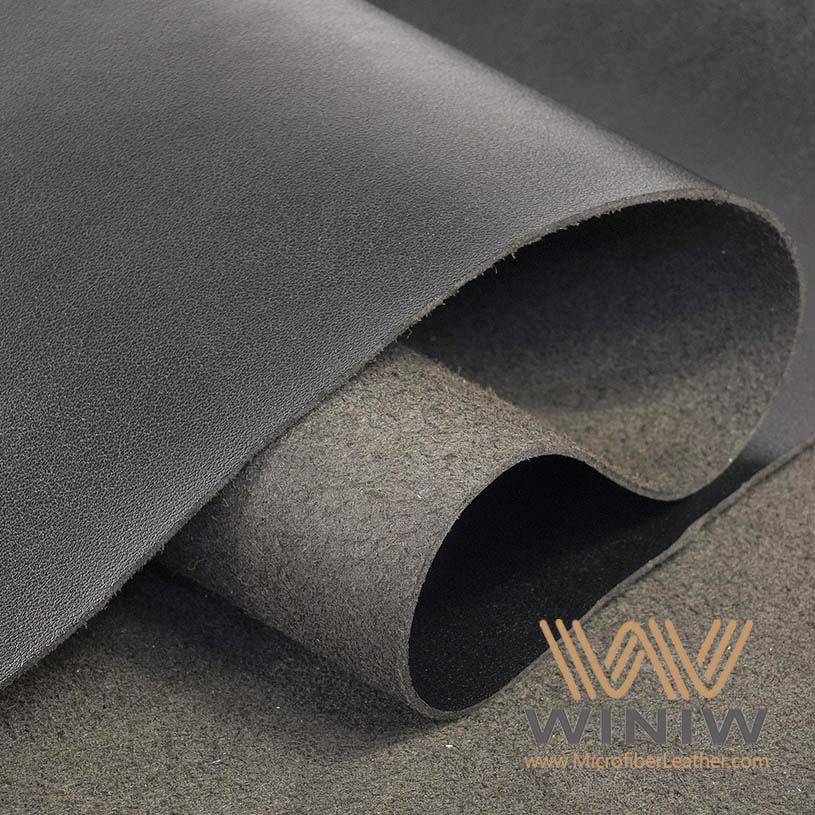

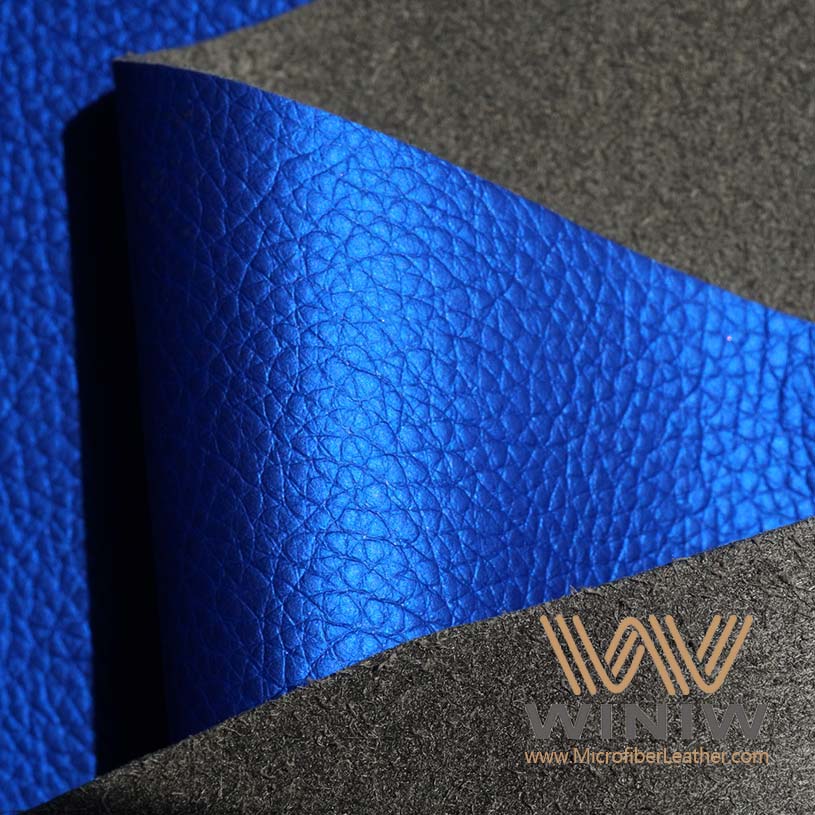

Da sợi nhỏ Nổi bật là một giải pháp thay thế thân thiện với môi trường cho da truyền thống. Nhiều nhà sản xuất hiện nay sử dụng lớp phủ polyester tái chế và polyurethane gốc nước, giúp giảm thiểu phát thải hóa chất và tiêu thụ năng lượng. Là vật liệu không có nguồn gốc từ động vật, da sợi nhỏ hỗ trợ đa dạng sinh học và tránh được những lo ngại về đạo đức như da thật. Da giả cung cấp các giải pháp sợi nhỏ tiên tiến, kết hợp giữa độ bền và phong cách. So với da truyền thống và da thuần chay, sợi nhỏ mang đến một lựa chọn linh hoạt và bền vững cho những người tiêu dùng muốn lựa chọn có trách nhiệm.Điểm nổi bậtDa sợi nhỏ là một giải pháp thay thế thân thiện với môi trường cho da truyền thống, được làm từ sợi tổng hợp và polyurethane gốc nước.Vật liệu này hỗ trợ phúc lợi động vật bằng cách hoàn toàn không có thành phần từ động vật, thu hút người tiêu dùng coi trọng sự lựa chọn có đạo đức.Sản xuất da sợi nhỏ sử dụng ít nước và năng lượng hơn đáng kể so với da thật, giúp giảm tác động đến môi trường.Độ bền của da sợi nhỏ có nghĩa là sản phẩm có tuổi thọ lâu hơn, ít gây lãng phí và ít phải thay thế hơn theo thời gian.Da sợi nhỏ rất đa năng, phù hợp với nhiều ứng dụng khác nhau bao gồm thời trang, nội thất ô tô và trang chủ đồ đạc.Nhiều nhà sản xuất, như Faux Leathers, sử dụng vật liệu tái chế trong sản xuất da sợi nhỏ, giúp tăng cường tính bền vững của sản phẩm.Da sợi nhỏ có thể tái chế, hỗ trợ nền kinh tế tuần hoàn và giảm thiểu chất thải chôn lấp khi sản phẩm hết vòng đời sử dụng.Chứng nhận đảm bảo rằng da sợi nhỏ đáp ứng các tiêu chuẩn về an toàn và môi trường, mang lại cho người tiêu dùng sự tin tưởng khi mua hàng.Da sợi nhỏ là gì?Da sợi nhỏ đại diện cho một bước tiến hiện đại trong thế giới vật liệu tổng hợp. Các nhà sản xuất đã thiết kế vật liệu này sao cho gần giống với da thật về cả hình dáng và kết cấu. Faux Leathers cung cấp da tổng hợp sợi nhỏ kết hợp giữa độ bền, tính linh hoạt và đặc tính thân thiện với môi trường. Chất liệu này nổi bật nhờ việc không sử dụng sản phẩm từ động vật và áp dụng các phương pháp sản xuất tiên tiến giúp giảm thiểu tác động đến môi trường.Thành phầnDa tổng hợp sợi nhỏ bao gồm hai lớp chính. Mỗi lớp đóng vai trò quan trọng trong hiệu suất và độ bền của vật liệu.Sợi tổng hợpLớp nền của da tổng hợp sợi nhỏ sử dụng sợi tổng hợp siêu mịn, thường được làm từ polyester hoặc nylon. Những sợi này được đan chặt chẽ để tạo nên một nền tảng chắc chắn và linh hoạt. Cấu trúc của sợi nhỏ mô phỏng các sợi collagen tự nhiên có trong da động vật. Thiết kế này mang lại cho vật liệu khả năng chống mài mòn tuyệt vời. Các nhà sản xuất lựa chọn sợi tổng hợp vì chúng mang lại chất lượng đồng đều và giúp giảm thiểu tiêu thụ tài nguyên.Lớp PULớp phủ polyurethane (PU) tạo nên lớp trên cùng của da tổng hợp sợi nhỏ. Lớp này mang lại cho vật liệu bề mặt mịn màng như da thật. Lớp PU tăng cường khả năng chống trầy xước, bám bẩn và phai màu. Nó cũng cho phép tạo ra nhiều màu sắc và họa tiết, giúp vật liệu phù hợp với nhiều ứng dụng. Sự kết hợp giữa sợi tổng hợp và PU tạo ra một vật liệu vừa nhẹ vừa dễ vệ sinh.Mẹo: Cấu trúc nhiều lớp của da tổng hợp sợi nhỏ khiến nó bền hơn và đa năng hơn nhiều loại vật liệu tổng hợp khác.Nó được làm như thế nàoCác nhà sản xuất sản xuất da tổng hợp sợi nhỏ thông qua một quy trình nhiều bước. Đầu tiên, họ dệt những sợi tổng hợp nhỏ thành một lớp vải không dệt dày đặc. Lớp vải này tạo thành nền tảng của vật liệu. Tiếp theo, họ phủ một lớp polyurethane lên bề mặt. Lớp PU thường là gốc nước, giúp giảm thiểu phát thải hóa chất và tiêu thụ năng lượng trong quá trình sản xuất.Quy trình sản xuất da tổng hợp sợi nhỏ tránh sử dụng hóa chất độc hại và không tạo ra khí nhà kính. Nó tiêu thụ ít nước và năng lượng hơn so với sản xuất da truyền thống. Phương pháp này hỗ trợ tính bền vững môi trường và phù hợp với các giá trị của các thương hiệu như Faux Leathers.Loại daNguyên liệu thôCấu trúc và quy trìnhCông dụngDa sợi nhỏSợi tổng hợp, polyurethaneVải không dệt đế sợi nhỏ, lớp phủ PUGiày dép, đồ nội thất, túi xách, đồ thể thaoDa thậtDa động vậtDa động vật đã thuộc và xử lýGiày dép, đồ nội thất, phụ kiệnDa tổng hợpVải không dệt sợi tổng hợp, polyurethaneVải không dệt tẩm, lớp hạt polyurethane vi xốpGiày dép, túi xách, phụ kiệnDa tổng hợp sợi nhỏ khác với da thật và các loại da tổng hợp khác ở một số điểm sau:Da sợi nhỏ sử dụng sợi tổng hợp và lớp PU, trong khi da thật được làm từ da động vật.Cấu trúc của da tổng hợp sợi nhỏ mô phỏng các sợi collagen tự nhiên, mang lại độ bền vượt trội.Da tổng hợp sợi nhỏ được sử dụng trong nhiều loại sản phẩm khác nhau do tính linh hoạt và thân thiện với môi trường.Da tổng hợp sợi nhỏ là một giải pháp thay thế bền vững cho các vật liệu truyền thống. Thành phần và quy trình sản xuất của nó giúp giảm thiểu tiêu thụ tài nguyên và tác động đến môi trường. Các thương hiệu như Faux Leathers không ngừng đổi mới, cung cấp da sợi nhỏ chất lượng cao cho nhiều ngành công nghiệp.Lợi ích sinh tháiTiết kiệm tài nguyênSử dụng nướcSản xuất da sợi nhỏ sử dụng ít nước hơn nhiều so với phương pháp thuộc da truyền thống. Da thật cần một lượng nước lớn để ngâm, giặt và nhuộm da động vật. Ngược lại, da sợi nhỏ sử dụng sợi tổng hợp và lớp phủ polyurethane, vốn cần ít nước hơn nhiều trong quá trình sản xuất. Nhiều nhà sản xuất cũng sử dụng vật liệu tái chế, giúp giảm thiểu tác động đến môi trường.Da sợi nhỏ thường được coi là thân thiện với môi trường hơn da thật.Để sản xuất ra nó cần lượng nước, đất và năng lượng khác nhau.Thường được làm từ vật liệu tái chế, giúp giảm tác động đến môi trường.Faux Leathers thể hiện trách nhiệm với môi trường bằng cách lựa chọn các quy trình tiết kiệm nước. Phương pháp này hỗ trợ tính bền vững và góp phần bảo vệ tài nguyên thiên nhiên cho các thế hệ tương lai.Sử dụng năng lượngNăng lượng cần thiết để sản xuất da vi sợi thấp hơn đáng kể so với da thật. Quy trình chế biến da truyền thống đòi hỏi nhiều công đoạn tiêu tốn năng lượng như xử lý, sấy khô và xử lý hóa chất. Sản xuất da vi sợi sử dụng các kỹ thuật tiên tiến giúp tinh giản quy trình sản xuất và giảm mức tiêu thụ năng lượng. Nhiều nhà máy hiện nay sử dụng các nguồn năng lượng tái tạo, góp phần hỗ trợ mục tiêu phát triển bền vững.Vật liệu sợi nhỏ cũng được hưởng lợi từ dây chuyền sản xuất hiệu quả. Những dây chuyền này tối ưu hóa việc sử dụng năng lượng và giảm thiểu chất thải. Do đó, da sợi nhỏ nổi bật là một lựa chọn bền vững và thân thiện với môi trường cho cả nhà sản xuất và người tiêu dùng.Lượng khí thải thấpSản xuất sạch hơnQuy trình sản xuất da vi sợi tạo ra ít khí thải hơn so với quy trình chế biến da truyền thống. Ngành công nghiệp này đã áp dụng các quy trình được kiểm soát chặt chẽ, sử dụng nguyên liệu sinh học và kỹ thuật xử lý tối ưu. Những cải tiến này giúp giảm lượng khí thải carbon của các sản phẩm da vi sợi.Diện mạoChi tiếtHồ sơ phát thảiDa sợi nhỏ có hàm lượng carbon thấp có lượng phát thải carbon giảm đáng kể so với da truyền thống.Kỹ thuật sản xuấtCác quy trình được kiểm soát chặt chẽ tận dụng nguyên liệu sinh học và kỹ thuật xử lý tối ưu.Thực hành môi trườngCác nhà sản xuất đang đầu tư vào liên kết không dung môi và nguồn năng lượng tái tạo để giảm thiểu khí thải.Giám sát và Tối ưu hóaCác nền tảng phân tích nâng cao được sử dụng để theo dõi mức tiêu thụ năng lượng và lãng phí vật liệu theo thời gian thực.Faux Leathers ủng hộ sản xuất sạch hơn bằng cách đầu tư vào công nghệ hiện đại và các hoạt động bền vững. Những nỗ lực này phù hợp với cam kết của thương hiệu về tính bền vững và trách nhiệm với môi trường.Ít hóa chất hơnPhương pháp thuộc da truyền thống thường sử dụng hóa chất mạnh, có thể gây hại cho môi trường. Sản xuất da vi sợi tránh được nhiều chất này. Các nhà sản xuất sử dụng lớp phủ polyurethane gốc nước và thuốc nhuộm an toàn hơn. Điều này làm giảm nguy cơ ô nhiễm và biến da vi sợi trở thành vật liệu an toàn hơn, bền vững hơn.Nhiều nhà máy cũng giám sát chặt chẽ việc sử dụng hóa chất. Họ tuân thủ nghiêm ngặt các hướng dẫn để đảm bảo sản phẩm sợi nhỏ an toàn cho cả con người và môi trường. Việc tập trung vào việc giảm thiểu hóa chất này củng cố danh tiếng thân thiện với môi trường của da sợi nhỏ.Độ bềnTuổi thọ caoDa microfiber có độ bền ấn tượng. Tuổi thọ trung bình của da microfiber thông thường là 5-10 năm. Da microfiber chất lượng cao thậm chí có thể bền hơn. Tuổi thọ cao này đồng nghĩa với việc các sản phẩm làm từ microfiber ít phải thay thế hơn, góp phần đảm bảo tính bền vững.Da sợi nhỏ thường bền hơn và dễ chăm sóc hơn da thật.Da thật có thể cần được bảo dưỡng nhiều hơn để giữ được tình trạng tốt.Da sợi nhỏ có khả năng chống vết bẩn và hư hại do nước tốt hơn, giúp việc bảo quản dễ dàng hơn.Faux Leathers thiết kế các sản phẩm sợi nhỏ của mình để chịu được việc sử dụng hàng ngày. Khách hàng được hưởng lợi từ chất liệu đẹp mắt và bền bỉ theo thời gian.Ít chất thải hơnNhững vật liệu bền bỉ như da sợi nhỏ giúp giảm thiểu rác thải. Nhờ độ bền cao hơn và khả năng chống hư hỏng tốt hơn, các sản phẩm từ sợi nhỏ ít bị thải ra bãi rác hơn. Độ bền này hỗ trợ một nền kinh tế tuần hoàn, nơi sản phẩm được sử dụng càng lâu càng tốt.Da sợi nhỏ thường có tuổi thọ từ 5 đến 10 năm.Da thật có thể sử dụng được lâu hơn nhiều nếu được chăm sóc đúng cách.Da sợi nhỏ có khả năng chống vết bẩn và hư hại do nước tốt hơn, giúp việc bảo quản dễ dàng hơn.Tính bền vững vẫn là giá trị cốt lõi của Faux Leathers. Bằng cách cung cấp da sợi nhỏ bền lâu, thương hiệu này giúp khách hàng lựa chọn sản phẩm thân thiện với môi trường, có lợi cho sức khỏe.Không có động vậtKhông có sản phẩm từ động vậtDa sợi nhỏ mang lại lợi thế rõ ràng cho những người quan tâm đến phúc lợi động vật. Các nhà sản xuất tạo ra vật liệu này từ các thành phần nhân tạo, chẳng hạn như polyurethane và sợi siêu nhỏ, thay vì da động vật. Quy trình này đảm bảo không có động vật nào bị làm hại hoặc bị bóc lột. Nhiều tổ chức, bao gồm cả PETA, công nhận da sợi nhỏ là một lựa chọn thay thế thân thiện với người ăn chay. Những người lựa chọn da sợi nhỏ ủng hộ lối sống không tàn ác và góp phần giảm nhu cầu đối với các sản phẩm có nguồn gốc động vật.Da sợi nhỏ được làm từ vật liệu tổng hợp, không phải da động vật.Quá trình sản xuất không liên quan đến hành vi ngược đãi hay bóc lột động vật.Các lựa chọn thân thiện với người ăn chay hấp dẫn người tiêu dùng có ý thức bảo vệ môi trường.PETA liệt kê da sợi nhỏ là lựa chọn có trách nhiệm với môi trường, ít tác động đến môi trường hơn so với da thật.Faux Leathers thể hiện cam kết sản xuất có đạo đức. Các sản phẩm sợi nhỏ của thương hiệu này phù hợp với giá trị của những khách hàng muốn tránh xa vật liệu có nguồn gốc động vật.Sự đa dạng sinh họcViệc sản xuất da vi sợi giúp bảo vệ đa dạng sinh học. Da truyền thống phụ thuộc vào chăn nuôi gia súc, gây ra nạn phá rừng và mất môi trường sống trên diện rộng. Da vi sợi sử dụng sợi tổng hợp và polyurethane, do đó không góp phần gây ra những vấn đề môi trường này. Việc chuyển đổi từ da động vật sang da tự nhiên góp phần bảo tồn rừng và động vật hoang dã.Hoạt độngTác động đến đa dạng sinh họcChăn nuôi gia súc ở Amazon80% nạn phá rừng, mất đa dạng sinh học đáng kểSản xuất gia súc ở Queensland, Úc73% nạn phá rừng, nguy cơ tuyệt chủng của các loàiKhai hoang đất để sản xuất túi da BrazilSự phá hủy môi trường sốngĐất được khai hoang để làm giày daNguy cơ sa mạc hóa tăng caoSản xuất da vi sợi không đòi hỏi phải chuyển đổi đất đai quy mô lớn. Hàng triệu mẫu Anh (acre) đất ở Nam Mỹ bị khai hoang mỗi năm để chăn nuôi gia súc, dẫn đến xói mòn đất và tăng nguy cơ cháy rừng. Bằng cách lựa chọn vi sợi, các nhà sản xuất và người tiêu dùng đang góp phần bảo vệ môi trường sống tự nhiên và giảm thiểu mối đe dọa đối với các loài động vật có nguy cơ tuyệt chủng.Lưu ý: Da sợi nhỏ hỗ trợ đa dạng sinh học bằng cách giảm nhu cầu chăn nuôi gia súc và nạn phá rừng.Faux Leathers tiếp tục đổi mới với các vật liệu không có nguồn gốc từ động vật. Thương hiệu tập trung vào các giải pháp sợi siêu nhỏ, giúp khách hàng đưa ra lựa chọn có lợi cho cả động vật và môi trường.Da sợi nhỏ so với da thậtTác động môi trườngKhi so sánh da vi sợi và da thật, sự khác biệt về môi trường trở nên rõ ràng. Sản xuất da vi sợi sử dụng sợi tổng hợp và polyurethane, nghĩa là không phụ thuộc vào nguyên liệu động vật. Quy trình này giúp giảm nhu cầu chăn nuôi, một nguồn phát thải khí nhà kính và nạn phá rừng chính. Mặt khác, da thật được làm từ da động vật. Chăn nuôi gia súc để lấy da đòi hỏi một lượng lớn đất đai, nước và thức ăn chăn nuôi. Nó cũng thải ra khí mê-tan, một loại khí nhà kính mạnh.Sản xuất da vi sợi sử dụng ít nước hơn so với thuộc da truyền thống. Quy trình này tránh được các hóa chất độc hại thường có trong thuộc da động vật, vốn thường gây ô nhiễm nguồn nước và ảnh hưởng đến hệ sinh thái địa phương. Tuy nhiên, da vi sợi sử dụng vật liệu có nguồn gốc từ dầu mỏ. Những vật liệu này đòi hỏi năng lượng và tài nguyên để sản xuất, và chúng không thể phân hủy sinh học. Tuy nhiên, nhiều nhà sản xuất, bao gồm cả Da giả, vẫn sử dụng vật liệu tái chế và lớp phủ gốc nước để giảm thiểu tác động đến môi trường.Quá trình sản xuất da sợi nhỏ sử dụng ít nguyên liệu thô từ động vật hơn, khiến nó thân thiện với môi trường hơn so với da thật.Da thật có thể phân huỷ sinh học nhưng lại chứa hóa chất trong quá trình thuộc da và khí thải từ gia súc.Sản xuất da sợi nhỏ giúp tránh ô nhiễm nguồn nước liên quan đến quá trình thuộc da động vật.Faux Leathers tiếp tục cải tiến quy trình bằng cách đầu tư vào các phương pháp sản xuất sạch hơn và nguồn cung ứng bền vững. Các sản phẩm sợi nhỏ của thương hiệu mang đến một lựa chọn có trách nhiệm cho những ai muốn giảm thiểu tác động đến môi trường.Đạo đứcMối quan tâm về đạo đức đóng vai trò quan trọng trong việc lựa chọn giữa da vi sợi và da thật. Da vi sợi là vật liệu thuần chay. Nó không sử dụng sản phẩm hoặc phụ phẩm từ động vật. Phương pháp tiếp cận không tàn ác này thu hút những người tiêu dùng quan tâm đến phúc lợi động vật. Da vi sợi của Faux Leathers ủng hộ lối sống thuần chay và giúp giảm nhu cầu chăn nuôi.Sản xuất da động vật đặt ra nhiều vấn đề đạo đức. Việc này liên quan đến việc nuôi và giết mổ động vật, điều mà nhiều người cho là không thể chấp nhận được. Quá trình này cũng góp phần gây ô nhiễm nguồn nước và phát thải khí nhà kính. Các hóa chất được sử dụng trong quá trình thuộc da động vật có thể ngăn chặn quá trình phân hủy sinh học và gây ô nhiễm môi trường địa phương.Da giả, bao gồm da sợi nhỏ, không thử nghiệm trên động vật và không sử dụng sản phẩm từ động vật.Nó làm giảm tác động đến môi trường liên quan đến sản xuất da truyền thống, vốn gắn liền với chăn nuôi.Sản xuất da động vật góp phần gây ô nhiễm nguồn nước và phát thải khí nhà kính đáng kể.Quá trình thuộc da động vật sử dụng các hóa chất độc hại ngăn cản quá trình phân hủy sinh học và gây ô nhiễm hệ sinh thái địa phương.Cam kết sản xuất có đạo đức của Faux Leathers tạo nên sự khác biệt. Da sợi nhỏ của thương hiệu mang đến một lựa chọn thay thế vượt trội cho những ai coi trọng tính bền vững và phúc lợi động vật. Bằng cách lựa chọn vật liệu thuần chay, người tiêu dùng đang ủng hộ một tương lai có đạo đức và ý thức hơn về môi trường.Da sợi nhỏ so với da thuần chayNguồn vật liệuDa sợi nhỏ và da thuần chay đều là những lựa chọn thay thế không có nguồn gốc động vật cho da truyền thống. Tuy nhiên, nguồn gốc của chúng khác nhau. Da sợi nhỏ sử dụng sợi tổng hợp siêu mịn, chẳng hạn như polyester hoặc nylon, kết hợp với lớp phủ polyurethane. Cấu trúc này mang lại cảm giác và vẻ ngoài giống da thật. Các nhà sản xuất thường sử dụng vật liệu tái chế trong quá trình sản xuất sợi nhỏ, giúp giảm thiểu chất thải.Ngược lại, da thuần chay (vegan leather) có nguồn gốc từ nhiều nguồn thực vật hoặc tổng hợp. Một số loại sử dụng vật liệu tự nhiên như lá dứa, xương rồng hoặc vỏ nho. Một số khác sử dụng polymer tổng hợp. Việc lựa chọn nguyên liệu thô ảnh hưởng đến kết cấu, độ bền và tác động môi trường của sản phẩm cuối cùng. Faux Leathers cung cấp cả lựa chọn da sợi nhỏ và da thuần chay, cho phép khách hàng lựa chọn loại phù hợp nhất với nhu cầu của mình.Lưu ý: Nguyên liệu gốc đóng vai trò quan trọng trong tính bền vững và hiệu suất của từng loại da thay thế.Hiệu suấtHiệu suất khác nhau giữa da sợi nhỏ và da thuần chay, tùy thuộc vào thành phần của chúng. Da sợi nhỏ nổi bật với độ bền cao. Nó chống mài mòn và rách, phù hợp cho các sản phẩm sử dụng hàng ngày, chẳng hạn như túi xách, đồ nội thất và dụng cụ thể thao. Khả năng chống nước và chống bám bẩn càng làm tăng thêm sức hấp dẫn của da, đặc biệt là đối với những vật dụng cần vệ sinh dễ dàng.Hiệu suất của da thuần chay phụ thuộc vào từng loại cụ thể. Một số loại da có nguồn gốc thực vật có độ bền tốt, trong khi một số khác có thể dễ bị ố hoặc hư hỏng do nước. Tính linh hoạt của da thuần chay cũng khác nhau. Một số loại phù hợp với phụ kiện thời trang, trong khi một số khác lại phù hợp với các ứng dụng trong thiết kế ô tô hoặc nội thất.Bảng dưới đây nêu bật những điểm khác biệt chính:Tính năngDa sợi nhỏDa thuần chayĐộ bềnCao; chịu được sự hao mònThay đổi; thường bền nhưng tùy thuộc vào loạiKhả năng chống nướcCó; chống nướcCó thể khác nhau; một số loại có thể không chống nướcChống bám bẩnCó; chống bám bẩnThay đổi; một số loại có thể dễ bị ốTính linh hoạtThích hợp cho túi xách, quần áo, đồ nội thấtThay đổi; tùy thuộc vào loại da thuần chay cụ thểTác động môi trườngBao gồm các sản phẩm có nguồn gốc từ dầu mỏNói chung tác động thấp hơn, nhưng thay đổi tùy theo loạiKhả năng thoáng khíÍt thoáng khí hơn da thậtThay đổi; một số loại có thể thoáng khí hơnXét về tính bền vững, cả hai loại vật liệu này đều có ưu điểm vượt trội hơn da động vật. Da vi sợi và da thuần chay tránh được khí thải mê-tan và chất thải hóa học liên quan đến quá trình thuộc da truyền thống. Những tiến bộ gần đây trong các phương pháp sản xuất thân thiện với môi trường tiếp tục cải thiện hồ sơ môi trường của chúng. Lượng khí thải carbon của da nhân tạoDa nhân tạo, bao gồm cả sợi siêu nhỏ, có lượng khí thải CO2 thấp hơn nhiều so với da bò. Ví dụ, da nhân tạo có tác động khoảng 15,8 kg CO2e trên một mét vuông, trong khi da bò đạt 110,0 kg CO2e trên một mét vuông. Lượng nước sử dụng cũng khác nhau đáng kể. Sản xuất da có thể cần hơn 17.000 lít nước cho một chiếc túi tote, trong khi da tổng hợp và da thực vật lại sử dụng ít hơn nhiều.Cả da sợi nhỏ và da thuần chay đều làm giảm nhu cầu chăn nuôi.Các nhà sản xuất tiếp tục phát triển các lựa chọn bền vững hơn cho cả hai loại vật liệu.Tổng tác động đến môi trường phụ thuộc vào toàn bộ vòng đời, từ khai thác nguyên liệu thô đến xử lý.Faux Leathers cung cấp đa dạng các sản phẩm da vi sợi và da thuần chay. Khách hàng có thể lựa chọn dựa trên sở thích của mình, dù là độ bền, tính bền vững hay tính linh hoạt.Tác động thực tếTái chếDa sợi nhỏ mang đến những giải pháp thiết thực cho việc quản lý cuối vòng đời sản phẩm. Nhiều nhà sản xuất thiết kế da sợi nhỏ có thể tái chế. Họ sử dụng sợi tổng hợp và lớp phủ polyurethane có thể được tách ra và xử lý để tái sử dụng. Tái chế giúp giảm thiểu chất thải chôn lấp và hỗ trợ nền kinh tế tuần hoàn. Một số công ty thu gom các sản phẩm sợi nhỏ đã qua sử dụng và gửi đến các cơ sở chuyên dụng. Các cơ sở này sẽ phân hủy vật liệu và thu hồi các thành phần có giá trị.Người tiêu dùng có thể kéo dài tuổi thọ của da sợi nhỏ bằng cách lựa chọn các sản phẩm có cấu trúc bền bỉ. Faux Leathers khuyến khích khách hàng chăm sóc sản phẩm và cân nhắc các lựa chọn tái chế khi sản phẩm hết hạn sử dụng. Nhiều trung tâm tái chế địa phương chấp nhận vật liệu tổng hợp. Một số thương hiệu cũng cung cấp chương trình thu hồi túi xách, đồ bọc hoặc phụ kiện đã qua sử dụng. Những chương trình này giúp duy trì nguồn tài nguyên quý giá và giảm thiểu tác động đến môi trường.Mẹo: Việc vệ sinh và bảo dưỡng đúng cách có thể kéo dài tuổi thọ của da sợi nhỏ, giúp việc tái chế ít thường xuyên hơn và hiệu quả hơn.Da sợi nhỏ chống bám bẩn và hư hại do nước, giúp sản phẩm bền lâu hơn. Độ bền này giúp giảm nhu cầu thay thế thường xuyên. Khi sản phẩm bị hao mòn, việc tái chế là một cách quản lý chất thải có trách nhiệm. Quy trình này hỗ trợ tính bền vững và giúp bảo tồn tài nguyên thiên nhiên.Chứng nhậnChứng nhận đóng vai trò quan trọng trong việc đảm bảo tính an toàn và bền vững của da sợi nhỏ. Da giả đáp ứng một số tiêu chuẩn quan trọng của ngành. Các chứng nhận này xác nhận sản phẩm không chứa chất độc hại và được sản xuất bằng phương pháp thân thiện với môi trường.Chứng nhậnSự miêu tảTiêu chuẩn RoHSHạn chế các chất nguy hiểmEU REACHĐăng ký, Đánh giá, Cấp phép và Hạn chế Hóa chấtEN20345Tiêu chuẩn Châu Âu về giày an toànCác nhà sản xuất tuân thủ các hướng dẫn nghiêm ngặt để đạt được các chứng nhận này. ROHS hạn chế việc sử dụng vật liệu nguy hiểm trong sản xuất. EU REACH quy định các hóa chất nhằm bảo vệ sức khỏe con người và môi trường. EN20345 đặt ra các tiêu chuẩn an toàn cho giày dép, đảm bảo sản phẩm đáp ứng các yêu cầu hiệu suất cao.Các tiêu chuẩn công nghiệp cũng hỗ trợ tính bền vững. Bảng sau đây cho thấy các tiêu chuẩn này tác động như thế nào đến quá trình sản xuất da vi sợi:Tiêu chuẩn ISOMục đíchTác động đến tính bền vữngTiêu chuẩn ISO 9001:2015Nâng cao hệ thống quản lý chất lượngCải thiện chất lượng sản phẩmTiêu chuẩn ISO 14001:2015Thể hiện cam kết về quản lý môi trường và tính bền vữngĐảm bảo các hoạt động thân thiện với môi trườngTiêu chuẩn ISO 45001:2018Đảm bảo an toàn cho người lao động trong quá trình sản xuấtThúc đẩy điều kiện làm việc an toànKiểm tra ASTMĐánh giá độ bền màu, khả năng hấp thụ nước và độ ổn định của khu vựcĐảm bảo độ bền và an toàn của sản phẩmCác chất có hạiQuy trình chứng nhận kiểm tra hơn 1.000 chất độc hạiGiảm thiểu rủi ro về môi trường và sức khỏeCác tiêu chuẩn này yêu cầu kiểm tra và giám sát thường xuyên. Các nhà sản xuất đánh giá độ bền màu, khả năng hấp thụ nước và độ ổn định để đảm bảo an toàn cho sản phẩm. Quy trình chứng nhận kiểm tra hơn 1.000 chất độc hại, giảm thiểu rủi ro cho con người và hành tinh.Faux Leathers thể hiện cam kết về chất lượng và tính bền vững bằng cách đáp ứng các chứng nhận này. Khách hàng có thể tin tưởng rằng các sản phẩm da sợi nhỏ tuân thủ các tiêu chuẩn an toàn và môi trường toàn cầu. Phương pháp này hỗ trợ sản xuất có trách nhiệm và góp phần xây dựng một tương lai bền vững hơn.Ứng dụngCác sản phẩm da sợi nhỏ đã thay đổi nhiều ngành công nghiệp nhờ độ bền, tính linh hoạt và đặc tính thân thiện với môi trường. Các nhà thiết kế, nhà sản xuất và người tiêu dùng hiện nay tin tưởng sử dụng những vật liệu này cho nhiều mục đích khác nhau.Thời trangCác thương hiệu thời trang đã ưa chuộng các sản phẩm da sợi nhỏ vì khả năng mô phỏng vẻ ngoài và cảm giác của da thật, đồng thời mang lại hiệu suất vượt trội. Các nhà thiết kế sử dụng chất liệu này để tạo ra những chiếc túi xách, giày dép, áo khoác và phụ kiện thời trang. Tính chất nhẹ của da sợi nhỏ giúp chúng thoải mái khi mặc hàng ngày. Nhiều thương hiệu lựa chọn chất liệu này vì khả năng chống bám bẩn và trầy xước, đảm bảo sản phẩm luôn giữ được vẻ ngoài như mới theo thời gian.Túi xáchĐôi giàyÁo khoácPhụ kiệnCác sản phẩm da sợi nhỏ cho phép đa dạng màu sắc và họa tiết, mang đến cho các nhà thiết kế sự tự do sáng tạo. Khách hàng đánh giá cao tính dễ bảo trì và chất lượng bền lâu. Faux Leathers cung cấp cho các nhà mốt và nhà sáng tạo độc lập những vật liệu hỗ trợ các hoạt động bền vững.Lưu ý: Các sản phẩm da sợi nhỏ thời trang kết hợp phong cách, sự thoải mái và tính bền vững, khiến chúng trở thành lựa chọn ưu tiên của người tiêu dùng có ý thức bảo vệ môi trường.Ô tôCác nhà sản xuất ô tô ngày càng sử dụng các sản phẩm da sợi nhỏ cho nội thất xe hơi. Những vật liệu này bao phủ ghế ngồi, bảng điều khiển và ốp trang trí, mang lại cảm giác sang trọng mà không gây ảnh hưởng đến môi trường như da truyền thống. Da sợi nhỏ có độ bền xé và bong tróc cao, đảm bảo độ bền lâu dài ngay cả ở những khu vực dễ bị mài mòn. Khả năng chống mài mòn của chúng giúp nội thất xe luôn trông như mới, ngay cả sau nhiều năm sử dụng.Ghế ngồiBảng điều khiểnTrang trí nội thấtCác sản phẩm da sợi nhỏ góp phần cải thiện hiệu suất nhiên liệu nhờ đặc tính nhẹ của chúng. Chủ xe được hưởng lợi từ nội thất chống bám bẩn và chống tràn, giúp việc vệ sinh trở nên dễ dàng. Chất liệu không bị bong tróc hay lão hóa nhanh, duy trì tình trạng nguyên sơ. Nhiều thương hiệu ô tô hàng đầu đã áp dụng các sản phẩm da sợi nhỏ nhờ độ bền vượt trội và khả năng thân thiện với môi trường.Tính năngLợi íchĐộ bền xé/bócĐảm bảo tuổi thọKhả năng chống mài mònThích hợp cho các khu vực có độ mài mòn caoNhẹCải thiện hiệu quả sử dụng nhiên liệuChống bám bẩnTăng cường tính thực tếTrang chủ & ThêmCác sản phẩm da sợi nhỏ đã tìm được chỗ đứng trong gia đình và các ngành công nghiệp khác. Các nhà sản xuất đồ nội thất sử dụng vật liệu này để bọc nệm, mang đến một giải pháp thay thế tổng hợp dễ vệ sinh và bảo trì. Chủ nhà yêu thích những chiếc ghế sofa và ghế bành chống bám bẩn và chống mài mòn. Các sản phẩm da sợi nhỏ cũng xuất hiện trong túi xách, ví và quần áo, mang đến những lựa chọn bền bỉ và giá cả phải chăng.Túi xách và víQuần áo, chẳng hạn như áo khoác và quầnBọc đồ nội thấtThiết bị thể thao, bao gồm găng tay và giàyỐp lưng điện tử cho điện thoại và máy tính bảngHành lý và giường cho thú cưngCác nhà sản xuất thiết bị thể thao tin tưởng vào các sản phẩm da sợi nhỏ vì khả năng thấm hút ẩm và chống mài mòn. Vỏ thiết bị điện tử làm từ vật liệu này bảo vệ thiết bị khỏi trầy xước. Faux Leathers hỗ trợ nhiều ngành công nghiệp khác nhau bằng cách cung cấp các sản phẩm da sợi nhỏ đáp ứng nhiều nhu cầu khác nhau.Mẹo: Các sản phẩm da sợi nhỏ mang đến giải pháp thiết thực cho cuộc sống hàng ngày, từ đồ nội thất đến đồ dùng thể thao.Câu chuyện của khách hàng nhấn mạnh sự hài lòng với các sản phẩm da sợi nhỏ. Ví dụ, Decorative Fabrics Direct cung cấp vải bọc nội thất giữ nguyên chất lượng và vẻ ngoài, ngay cả khi sử dụng thường xuyên. Nhiều khách hàng khen ngợi độ bền và dễ dàng vệ sinh của những vật liệu này trong cả không gian nhà ở và thương mại.Thách thức và Tương laiXu hướng thị trườngNgành công nghiệp da vi sợi tiếp tục phát triển khi các xu hướng thị trường mới định hình tương lai. Tính bền vững nổi bật là động lực chính. Người tiêu dùng và nhà sản xuất tìm kiếm quy trình sản xuất thân thiện với môi trường và vật liệu sinh học để giảm lượng khí thải carbon. Đổi mới công nghệ dẫn đến cải thiện tính chất xúc giác và kết cấu bề mặt gần giống với da thật. Việc tùy chỉnh trở nên dễ dàng hơn thông qua in kỹ thuật số và hoàn thiện bề mặt tiên tiến, cho phép tạo ra các sản phẩm được thiết kế riêng theo sở thích cá nhân.Dệt may thông minh là một xu hướng đang phát triển khác. Các nhà sản xuất tích hợp các tính năng IoT vào sản phẩm, nâng cao trải nghiệm người dùng trong lĩnh vực ô tô và thời trang cao cấp. Sự phát triển của thương mại điện tử cũng tác động đến thị trường. Các kênh bán hàng trực tiếp đến người tiêu dùng mang lại khả năng tiếp cận rộng rãi hơn và khuyến khích đổi mới.Xu hướngSự miêu tảTính bền vữngNhu cầu lớn về quy trình sản xuất thân thiện với môi trường và vật liệu sinh học.Đổi mới công nghệNhững tiến bộ về tính chất xúc giác và kết cấu bề mặt mô phỏng da thật.Tùy chỉnhNhững cải tiến về in kỹ thuật số và hoàn thiện bề mặt cho phép tạo ra những sản phẩm phù hợp với người tiêu dùng.Dệt may thông minhTích hợp các tính năng IoT vào sản phẩm, nâng cao trải nghiệm người dùng trong ngành ô tô và thời trang.Tăng trưởng thương mại điện tửTăng cường tiếp cận thị trường và đổi mới thông qua các kênh trực tiếp đến người tiêu dùng.Faux Leathers đáp ứng những xu hướng này bằng cách cung cấp các giải pháp da sợi nhỏ đáp ứng nhu cầu của người tiêu dùng hiện đại. Thương hiệu tập trung vào tính bền vững, khả năng tùy chỉnh và công nghệ tiên tiến để luôn dẫn đầu thị trường.Sự đổi mớiSự đổi mới thúc đẩy ngành công nghiệp sợi nhỏ phát triển. Các nhà sản xuất hiện nay sử dụng vật liệu tái chế và phát triển các sản phẩm phân hủy sinh học để giảm thiểu tác động đến môi trường. Tính chất kháng khuẩn đã trở nên quan trọng, đặc biệt là trong lĩnh vực chăm sóc sức khỏe. Da sợi nhỏ được tẩm chất kháng khuẩn giúp chống lại nguy cơ lây nhiễm chéo. Những vật liệu này cải thiện vệ sinh và sự thoải mái cho bệnh nhân trong nội thất y tế.Những tiến bộ gần đây bao gồm bề mặt tự phục hồi và các giải pháp thông minh. Tích hợp IoT cho phép sản phẩm tương tác với người dùng, gia tăng giá trị trong các ứng dụng ô tô và thời trang cao cấp. Thị trường mở rộng vượt ra ngoài các ứng dụng truyền thống, với da sợi nhỏ hiện đang đóng vai trò quan trọng trong việc phục hồi sức khỏe cộng đồng.Faux Leathers dẫn đầu trong công nghệ da sợi nhỏ. Thương hiệu này ủng hộ tính bền vững môi trường bằng cách thúc đẩy các giải pháp thay thế thân thiện với môi trường cho da truyền thống. Chủ nghĩa tiêu dùng có đạo đức làm tăng nhu cầu đối với các sản phẩm không thử nghiệm trên động vật, định vị microfiber là một giải pháp có trách nhiệm. Những tiến bộ công nghệ nâng cao chất lượng và hiệu suất, khiến da tổng hợp trở nên hấp dẫn hơn. Sự hỗ trợ về mặt quy định khuyến khích việc áp dụng thông qua các chính sách thúc đẩy các hoạt động bền vững. Hiệu quả về chi phí mang lại khoản tiết kiệm dài hạn nhờ độ bền và khả năng bảo trì thấp.Nhân tốĐóng góp cho sự phát triển của da sợi nhỏTính bền vững của môi trườngThúc đẩy nhu cầu về các giải pháp thay thế thân thiện với môi trường.Chủ nghĩa tiêu dùng có đạo đứcTăng nhu cầu về các sản phẩm không thử nghiệm trên động vật.Tiến bộ công nghệNâng cao chất lượng và hiệu suất.Hỗ trợ pháp lýKhuyến khích áp dụng thông qua các chính sách bền vững.Hiệu quả về chi phíMang lại hiệu quả tiết kiệm và độ bền lâu dài.Lưu ý: Faux Leathers tiếp tục đầu tư vào nghiên cứu và phát triển, đảm bảo rằng da sợi nhỏ luôn đi đầu về đổi mới và tính bền vững. Da sợi nhỏ nổi bật là một lựa chọn thay thế bền vững cho người tiêu dùng có ý thức bảo vệ môi trường. Vật liệu này giải quyết các vấn đề đạo đức và giảm thiểu tác động đến môi trường. Faux Leathers cung cấp các giải pháp sợi nhỏ tiên tiến, kết hợp giữa độ bền và phong cách. Bảng dưới đây nêu bật những ưu điểm chính về thân thiện với môi trường:Điểm chínhSự miêu tảGiải pháp thay thế bền vữngDa sợi nhỏ hấp dẫn người tiêu dùng có ý thức bảo vệ môi trường.Những cân nhắc về mặt đạo đứcVật liệu này hỗ trợ quyền động vật và giảm thiểu tác hại đến môi trường.Tác động môi trườngSản xuất sợi siêu nhỏ giúp giảm ô nhiễm so với da truyền thống.Vật liệu sáng tạoNhững tiến bộ trong sản xuất sinh học giúp nâng cao tính thân thiện với môi trường.Hãy cân nhắc sử dụng sợi microfiber cho dự án hoặc lần mua sắm tiếp theo của bạn. Khám phá các sản phẩm của Faux Leathers để hỗ trợ tính bền vững và phong cách.Câu hỏi thường gặpDa sợi nhỏ được làm từ gì?Da microfiber chứa các sợi tổng hợp siêu mịn và lớp phủ polyurethane (PU). Các nhà sản xuất dệt các sợi thành một lớp nền dày đặc, sau đó phủ lớp PU để tăng độ bền và tạo vẻ ngoài giống da thật. Làm thế nào để vệ sinh da sợi nhỏ?Dùng khăn ẩm và xà phòng nhẹ để vệ sinh da sợi nhỏ. Tránh sử dụng hóa chất mạnh. Vệ sinh thường xuyên giúp duy trì vẻ ngoài của chất liệu và kéo dài tuổi thọ. Da sợi nhỏ có thân thiện với môi trường không?Da sợi nhỏ hỗ trợ tính bền vững. Nó sử dụng ít tài nguyên hơn da thật và tránh sử dụng các sản phẩm từ động vật. Nhiều nhà sản xuất, bao gồm cả Da giả, sử dụng vật liệu tái chế và lớp phủ gốc nước để giảm thiểu tác động đến môi trường. Da sợi nhỏ có thể tái chế được không?Nhiều sản phẩm da sợi nhỏ có thể tái chế. Các nhà sản xuất thiết kế chúng để dễ dàng phân loại và xử lý. Tái chế giúp giảm thiểu chất thải chôn lấp và hỗ trợ nền kinh tế tuần hoàn. Bạn có thể sử dụng da sợi nhỏ ở đâu?Da sợi nhỏ thích hợp cho túi xách, giày dép, đồ nội thất, nội thất ô tô và dụng cụ thể thao. Độ bền và tính linh hoạt của nó giúp nó phù hợp với nhiều ngành công nghiệp. Da sợi nhỏ của Faux Leathers đạt được những chứng nhận nào?Da vi sợi của Faux Leathers đáp ứng các tiêu chuẩn như ROHS, EU REACH và EN20345. Các chứng nhận này xác nhận quy trình sản xuất an toàn, chất lượng và thân thiện với môi trường. Da sợi nhỏ có độ bền bao lâu?Da microfiber chất lượng cao có độ bền từ 5 đến 10 năm hoặc hơn. Khả năng chống bám bẩn, trầy xước và phai màu của da microfiber đảm bảo sản phẩm luôn đẹp mắt và bền bỉ theo thời gian. Da sợi nhỏ có phải không có nguồn gốc từ động vật không?Da microfiber không chứa thành phần động vật. Các nhà sản xuất sử dụng sợi tổng hợp và polyurethane, khiến nó trở thành lựa chọn thân thiện với người ăn chay và không thử nghiệm trên động vật.